Deeper Drive into our Circuitry

Inside the Brain of Smart Flooring: The Unsung Hero—Readout Electronics

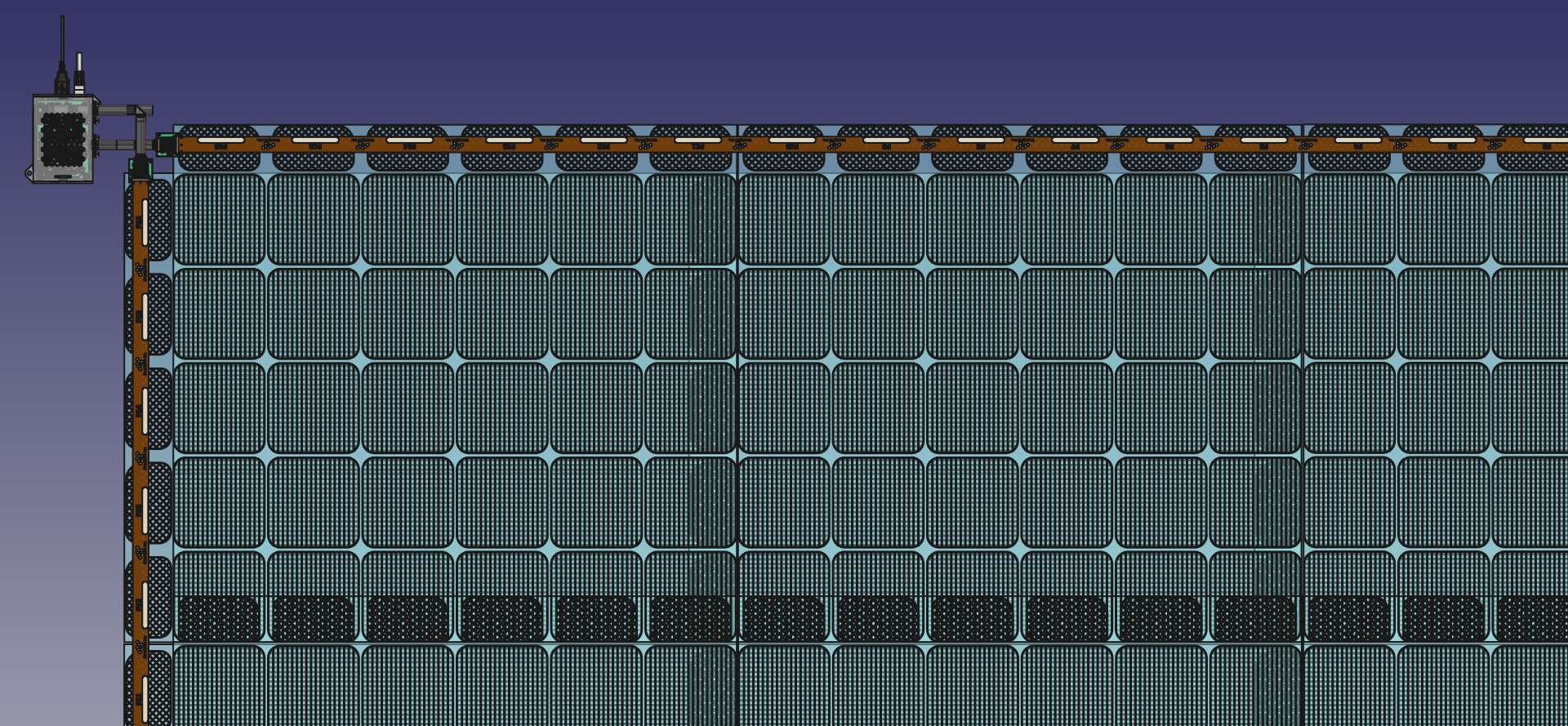

When we talk about Scanalytics’ smart flooring technology, it’s easy to fixate on the visible innovation—the underlayment packed with sensors, the elegant dashboard visualizations, the seamless integration into facilities. But there’s a silent powerhouse underneath it all that brings the entire system to life: the readout electronics.

These components are the true interpreters of physical pressure into digital intelligence. They are the bridge between a step and a signal, between human behavior and actionable data. And their story—both in how they’re built and where the technology comes from—tells us a lot about Scanalytics’ commitment to innovation and scalability.

From $100 Laptop to Scalable Sensors

To understand how we got here, we need to take a short detour to the early 2000s and a visionary project called One Laptop Per Child (OLPC). This initiative aimed to deliver durable, affordable laptops—under $100—to children in developing countries. What it inadvertently sparked was a global acceleration in the miniaturization and cost-efficiency of electronics. In striving to make something extremely compact and power-efficient, OLPC catalyzed improvements in chip design, battery life, and embedded computing.

That movement indirectly shaped today’s maker culture, which birthed tools like the Raspberry Pi, Arduino boards, and other embedded systems. These became the foundation for rapid prototyping at low costs. At Scanalytics, we’re part of that lineage. The electronics that read the signals from our sensor mats are built on that same spirit of innovation—modular, lightweight, programmable, and easily manufacturable.

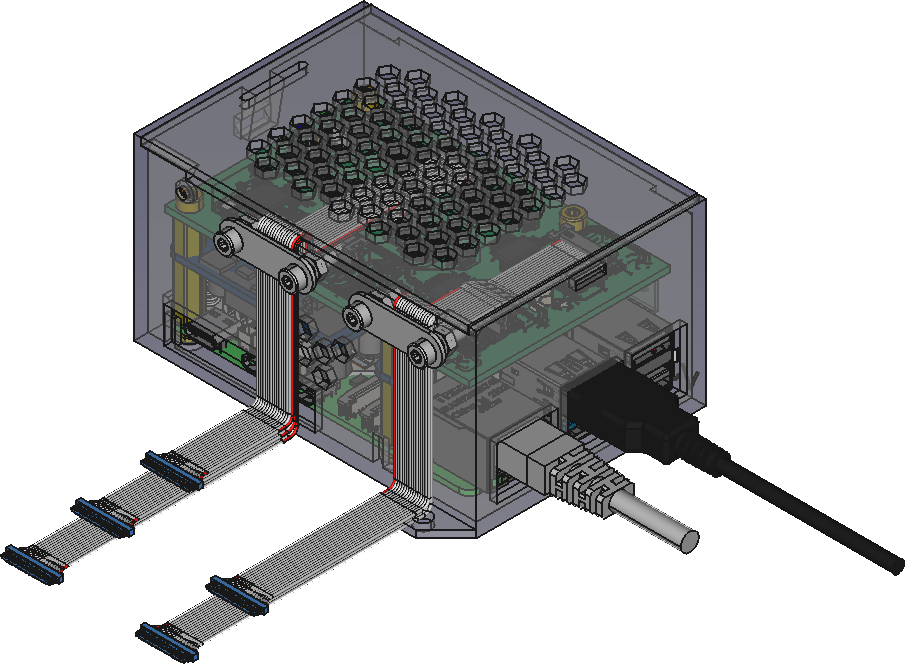

Our readout electronics are in each zone, hidden behind baseboards, counters, up in ceiling tiles, quietly collecting the data your building needs

What Are Readout Electronics?

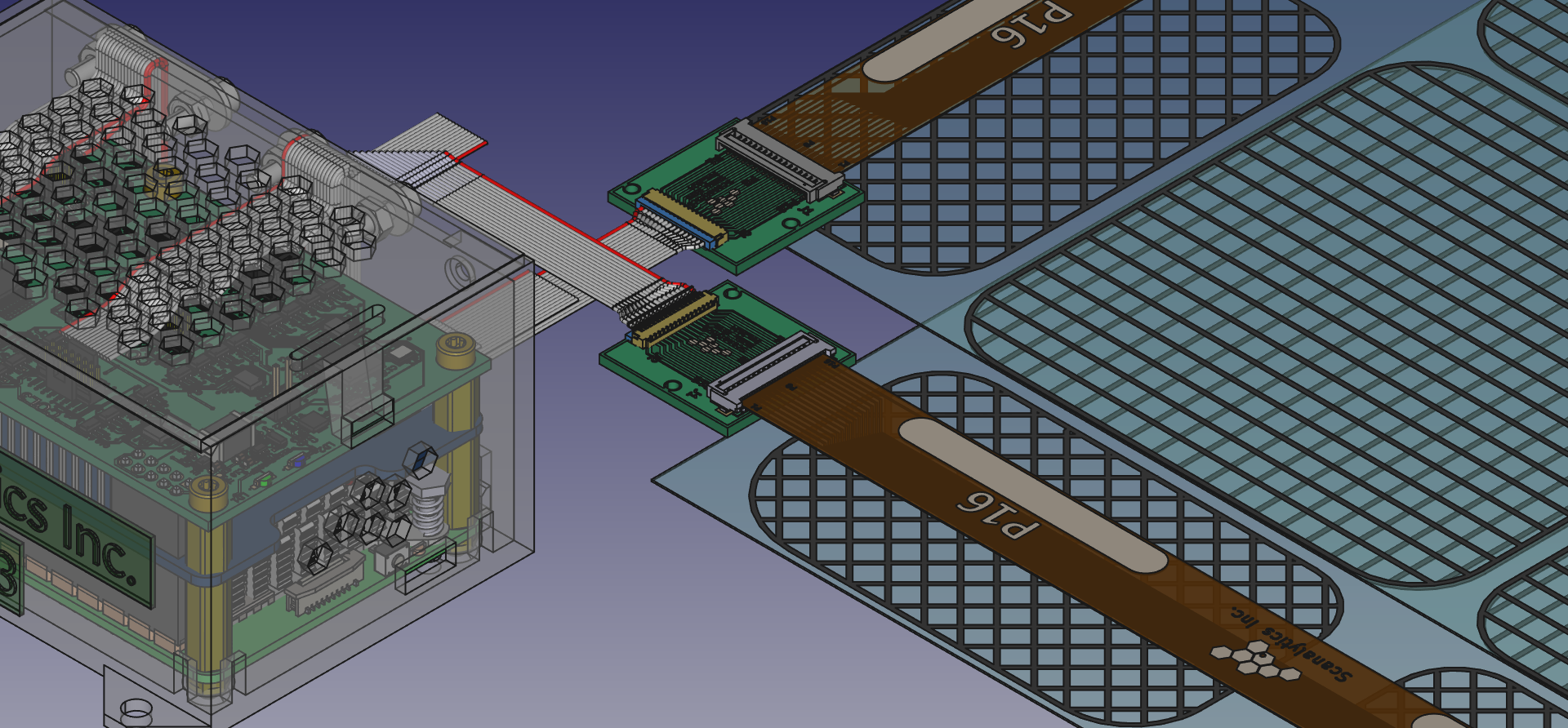

Think of the sensor-laden underlayment like a digital ear listening to the floor. Each square inch of our underlayment contains pressure-sensitive "pixels"—a grid of sensors that detect occupancy, movement, and engagement. But without readout electronics, it’s just data without context.

Our readout electronics do the following:

Capture analog signals from thousands of individual sensor points (pixels)

Digitize those signals with high fidelity and low latency

Run edge-level logic to preprocess and reduce raw data noise

Transmit structured data over PoE (Power over Ethernet) or wireless interfaces to our cloud-based analytics engine

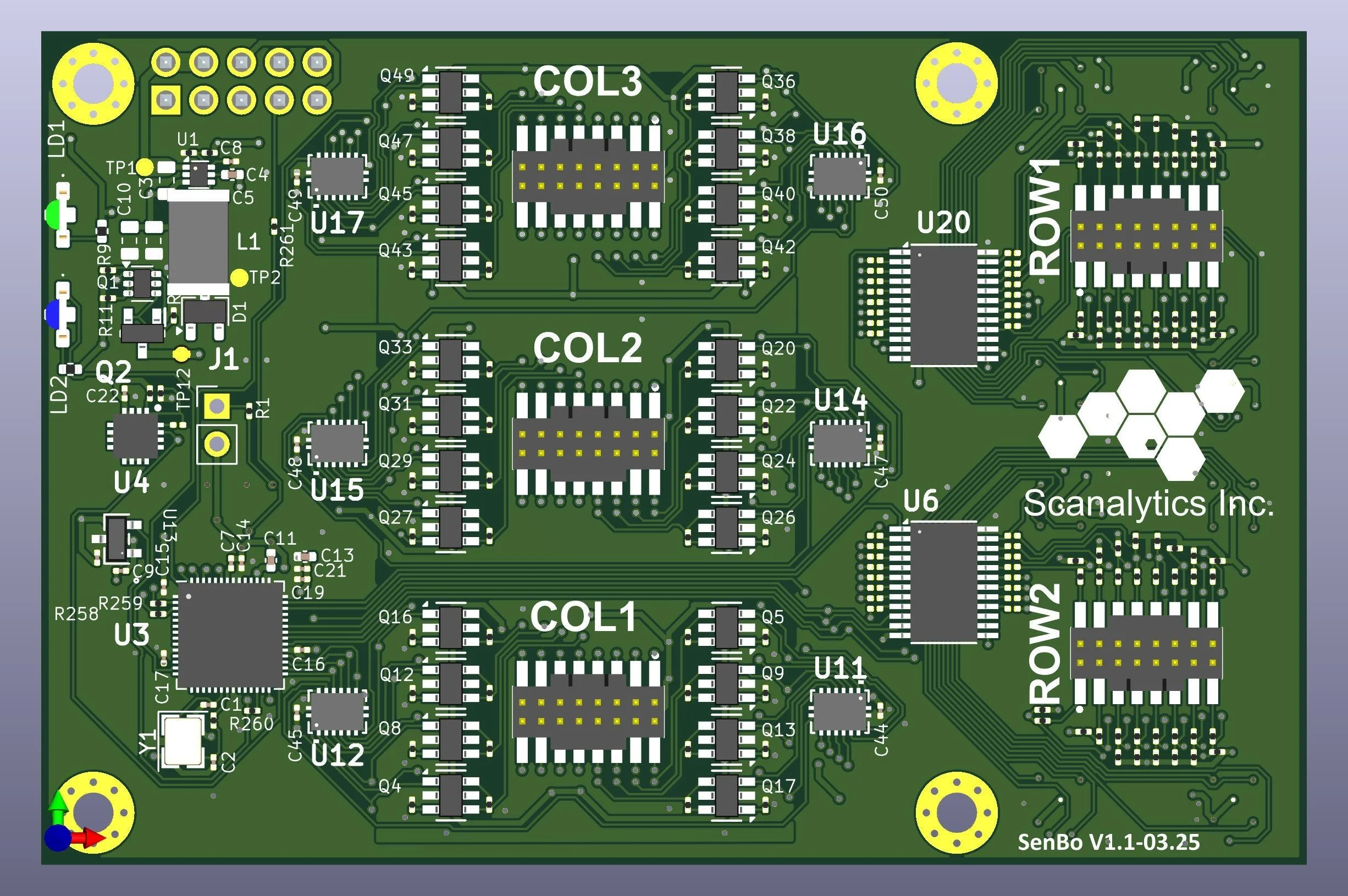

The readout device we use is similar in design philosophy to a Raspberry Pi—a compact, Linux-capable embedded system that can rapidly handle high data throughput. We pair off-the-shelf controllers and chips with custom-developed interfaces, adapting quickly through rapid prototyping cycles. This enables us to test, iterate, and refine our product without the massive overhead typically required for hardware development.

Modular, Scalable, and Resilient

As described in our product specifications, our flooring system is designed with modularity in mind. Each 4-inch “pixel” acts as an independent node in a larger sensor matrix. Even if individual components are damaged during installation or wear and tear, the overall system keeps functioning—thanks in part to the smart orchestration from the readout electronics.

This architecture provides several advantages:

Fault tolerance: Damaged pixels are automatically excluded or interpolated by the readout system.

Ease of replacement: Modular parts mean we can swap boards, not whole systems.

Deployment flexibility: Whether embedded under carpet tiles or vinyl, the readout components remain discreet and unobtrusive.

Real-Time Insights, Real-World Impact

The performance of these electronics isn’t theoretical—it’s field-proven. During large-scale deployments such as Paramount Studios and even at the Super Bowl, our systems captured real-time traffic, dwell time, and engagement patterns—down to the second. This wouldn’t be possible without readout hardware capable of managing massive input bandwidths and transmitting data without lag.

In healthcare environments, our electronics help detect patient mobility changes in real-time, improving safety and care delivery.

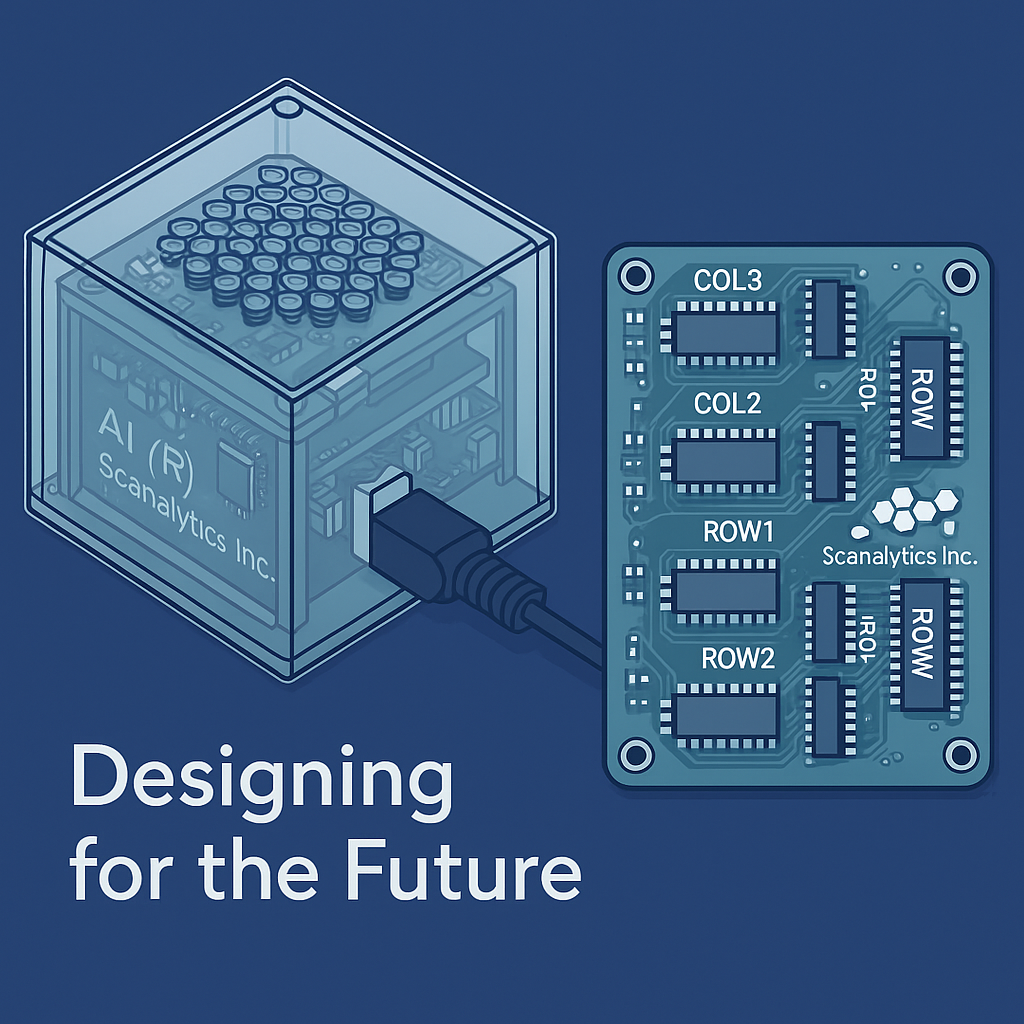

Designing for the Future

At Scanalytics, our R&D culture is centered on rapid iteration. By leveraging prototyping boards, custom PCBs, and open-source platforms, we bring new iterations of our readout electronics from concept to field-deployment in weeks, not months. This agility supports our broader mission: to digitize physical space and give our clients an intelligent window into how people interact with the built environment.

Whether installed during a flooring renovation or retrofitted into high-traffic areas, our embedded electronics enable commercial buildings to become dynamic, responsive environments.